Introduction:

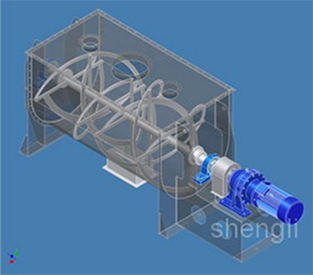

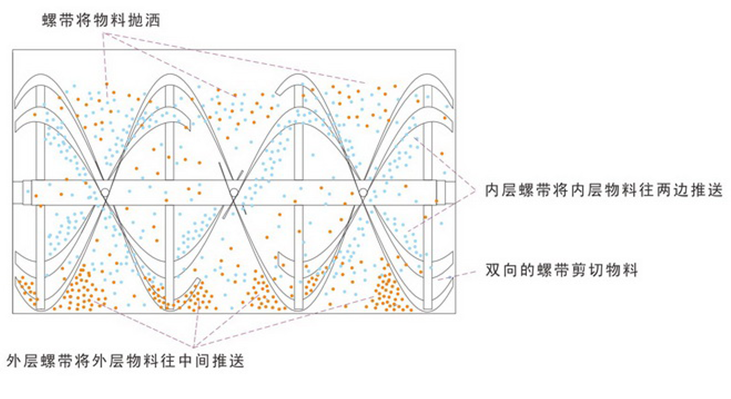

Ribbon mixer is horizontal batch mixers which feature two mixing blades of inner ribbons and outer ribbons! The blades move the materials in opposing directions, ensuring excellent cross-mixing of materials. This ribbon mixer is characterized by high mixing effect, large productivity, and a very low failure rate.

Ribbon mixer is widely powder, granules, liquid additives, slurry etc. like for moistening, agglomerating, and granulating materiasls, which is widely used in food,medicine,feed,chemical,fertilizer, new energy industries etc.

where requried, spray lines, side clean doors, high-speed choppers,heat or cold jacket,different functional coating can be installed to achieve the desired mixing effect

Features:

# Batch Mixer # Blender Machine # Food Powder Mixer # Horizontal Blender Machine

# Mixing Machine # Powder Blender # Horizontal Mixer Machine # mixing equipment # powder mixer

# Powder Ribbon blender # ribbon blender # Ribbon Mixer

1.material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321; besides, different material can also be used in combination.

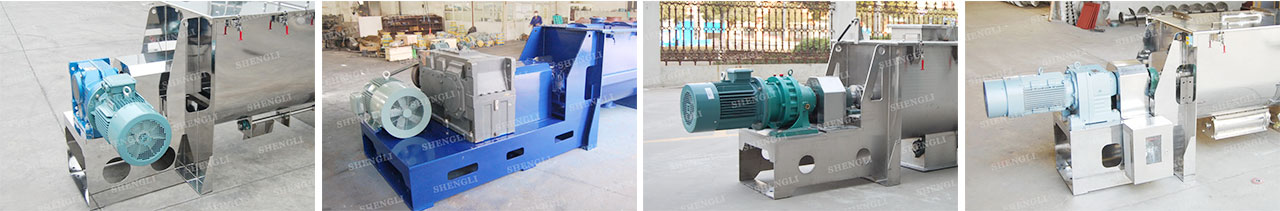

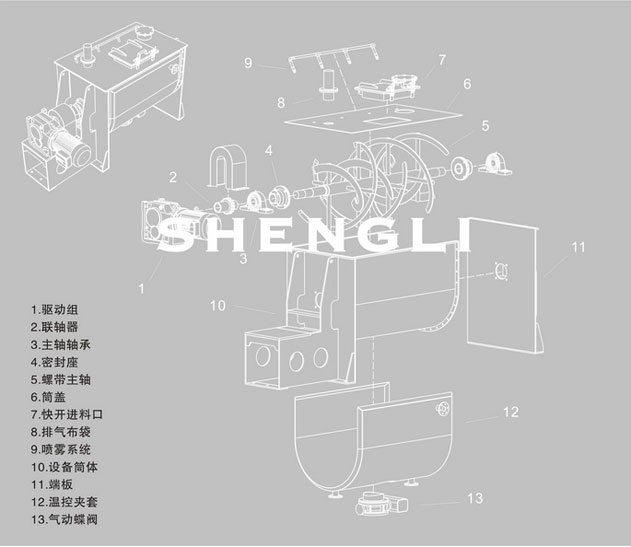

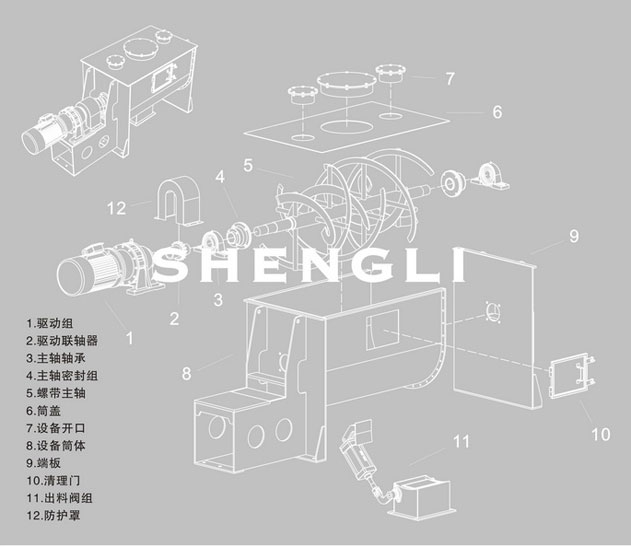

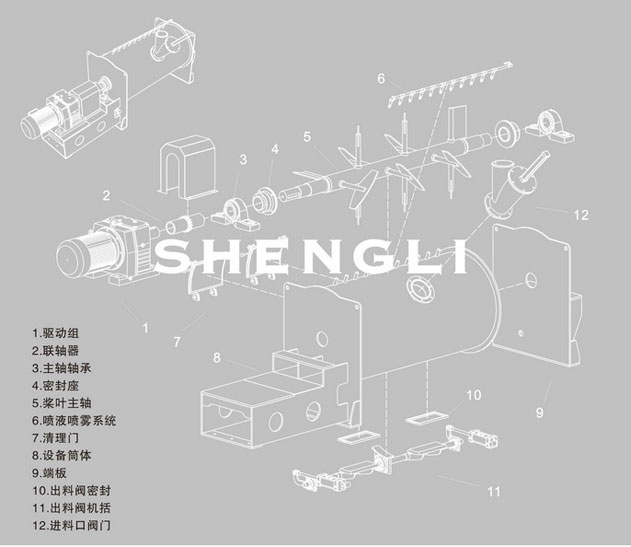

2.driven unit

The driven unit, power and output speed are varied according to different raw material, starting method, and processing.

Options for motor: general motors, explosion-proof motors, variable frequency motor, high efficiency and energy saving motor.

Commonly used reducers: R-series, K-series, and F-series gear box; cycloidal reducer, universal gear reducer, planetary gear reducer. Commonly motor-gearbox connection: direct connection, pulley connection, hydraulic coupler connection.

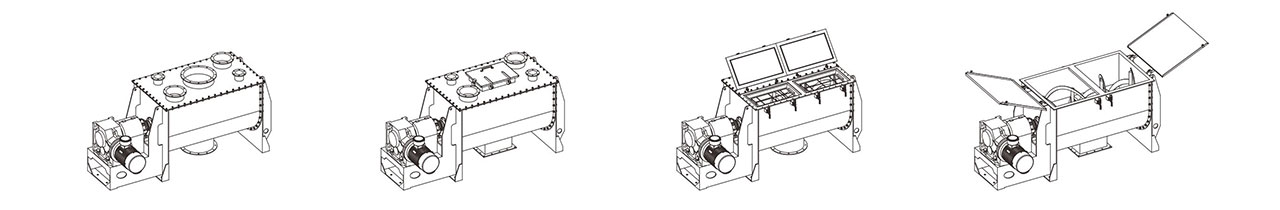

3.mixing unit

Different main shaft agitators can be equipped according to the properties of raw materials.

Materials commonly mixed are: different kinds of powder to be mixed with each other, batches mixing for the same material, powder with a small quantity of liquid, liquid with some powder, like slurry, thickening or diluting slurry, granule with powder, granule with granule, or agglomerated material breaking and mixing, and cooling or heating.

The main shaft agitator could be: inner and outer ribbon, paddle and ribbon, disconnected ribbon, and shaver-shaped agitator.

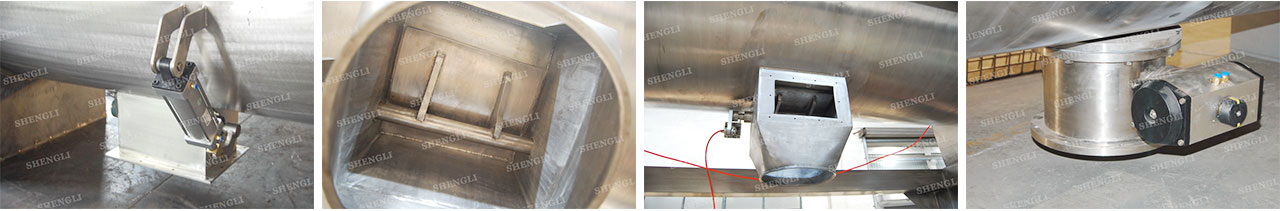

4.discharging unit

Standard valve for horizontal mixer is pneumatic planar flap valve. When close the valve, the planar flap match the mixing barrel perfectly, this makes no mixing dead zone and better mixing effect.

The drive types of valve are Manual, pneumatic, and electric.

Valves for consideration: powder spherical valve, cylinder valve, plum-blossom dislocation valve, butterfly valve, rotary valve etc.

Working principle:

Horizontal ribbon mixer is mainly combined with mixing barrel, agitator, driven unit.Untwist double ribbon are swirled with the main shaft in the U shape barrel. The outer ribbon push the material from the two ends to the centre, inner ribbon push the material from center to the two ends.Thus to achieve material convention

The discharging port is set in the bottom centre, with the help of the outer ribbon,the material can be discharged completely, and no dead zone.

|

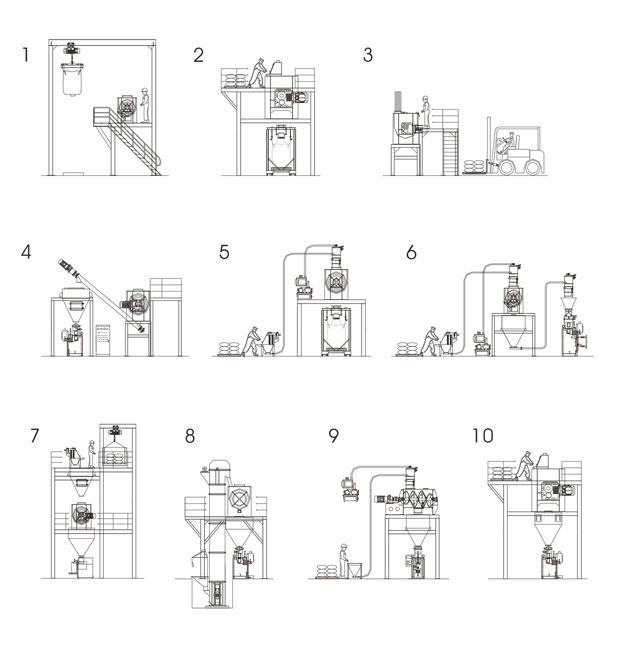

Configuration 1: using crane to hang jumbo bag material and feeding the mixer

|

|