Introduction:

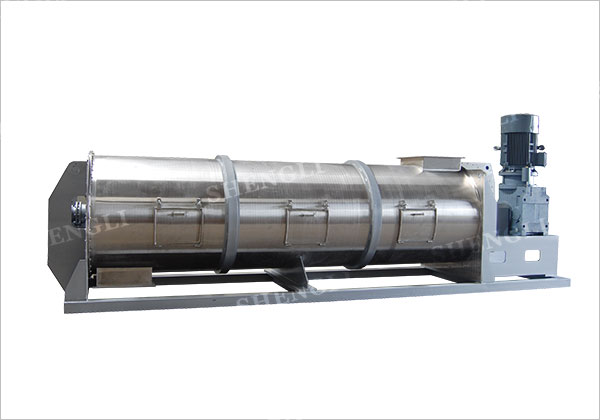

CM-series continuous mixer has single shaft and double shafts choice, it consists of a mixing vessel with an inlet at one end of the mixing drum, an outlet at the opposite end and a venting spout, one or two mixing shaft, transmission unit, and seal unit.

Plough or inclined paddle rotate as mixing tools, push the material constantly from feeding side to the outlet side, the quality of the mixture is achieved before the product reaches the mixer outlet. because of its non-stop process, it can match the large scale production line, Continuous Mixers are widely used for dry bulk solids (powders, granules), dry bulk solids + liquids (moistening + granulating), sludge or low-viscosity pastes.

In some cases, to obtain the desired mixing effect, separately driven high-speed choppers in the drum or baffle plate before the outlet can be installed.

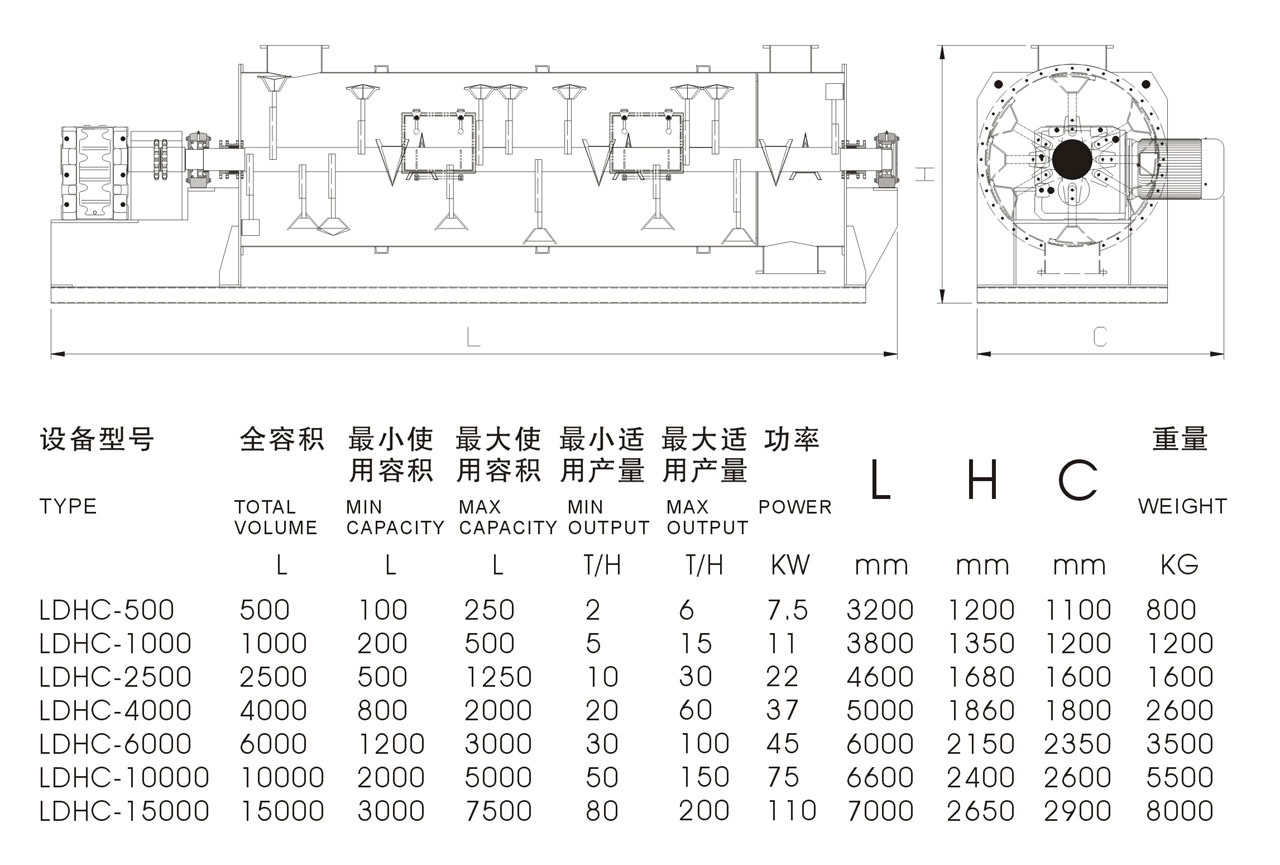

Technical Parameter:

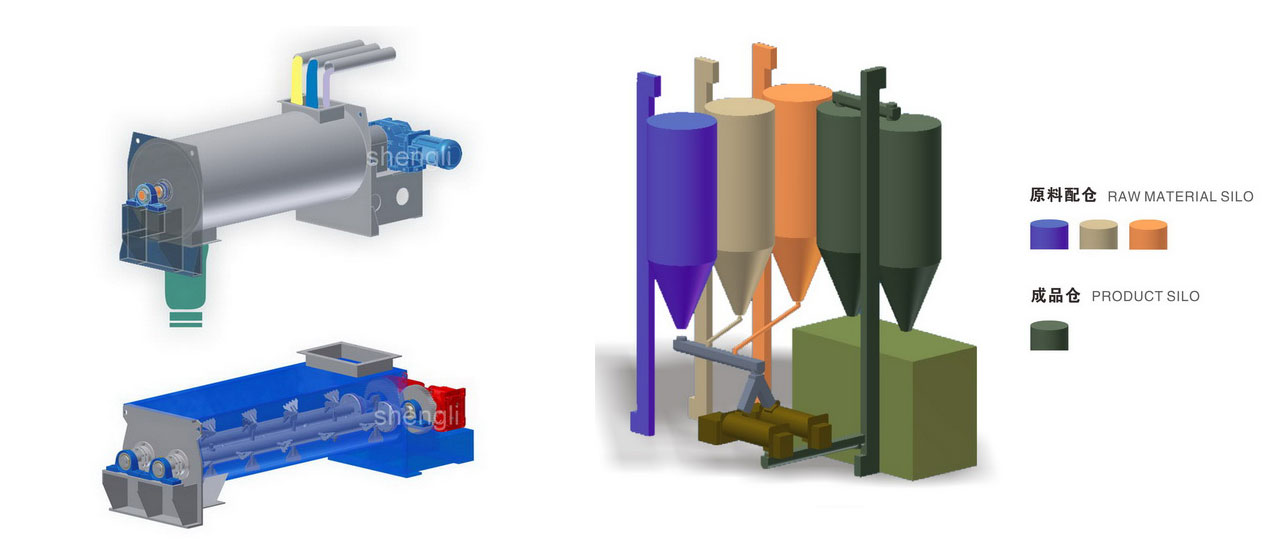

The CMS (Continuous single shaft plough mixer), focus on mixing, it can also be used as conveyor. With the special inner structure, it can adapt to a certain range of the feeding speed to achieve relevant productivity. With the uniform speed feeding equipment, it can mix material in a wide range, and make sure the consistency and stability of all the product.

CMD ( continuous double shaft paddle mixer) is characterized by maximizing the productivity. Materials are scattered during the vigorous mixing process, diffused and nobbed between the meshing space of the twin shafts. It can be applied to mix fiber and granules.

Notice for continuous mixer:

1. Make sure the stable and continuous feeding.

2. Make correct feeding speed ratio in accordance to the material formula.

3. Equipment under the discharging should handle the material in time and make sure no blockage of the material when discharging.

4. Small additives less than 5%, should be premixed before loading to continuous mixer.

5. Mixer productivity is determined by the speed of feeding system. Mixer model and size are determined by productivity, homogeneity and material property.